For many industrial facilities, hazardous gases are a grave danger to workers’ health and safety. Despite their obvious threat, two of the most common byproducts of industrial processes—carbon monoxide (CO) and carbon dioxide (CO2)—are colorless, odorless, and undetectable without detection systems. As such, a CO2 gas monitor is a vital piece of equipment to have in any confined spaces where CO and CO2 can accumulate.

Recognizing Danger

Due to its inherent dangers and qualities, CO poses a serious threat to anyone who may become exposed to it. As an asphyxiant gas, CO bonds to the hemoglobin in your blood and deprives your heart, brain, and body the necessary oxygen molecules they need to function. High enough concentrations can cause oxygen starvation.

Symptoms of acute CO poisoning include nausea, lethargy, dizziness, and confusion. When exposed to CO, a victim’s blood pressure will rise in an attempt to circulate more blood and oxygen through the body, resulting in their skin taking on a reddish color.

At higher levels of exposure, more severe symptoms will develop, such as lack of coordination, chest pain, and unconsciousness.

Types of Detection Systems

Installing a CO2 gas detector and other indoor air-quality testing systems, such as detector tubes, diffusion tubes, color badges, and can help improve the air quality in an at-risk area. It alerts your workers for possible exposure to dangerous levels of CO, CO2, and other hazardous contaminants.

You can use detection tubes to determine the CO concentration at any point in time; these devices work by pumping air through the detection media. When CO is present and within the detection limitations of the tube, the media changes color to indicate the concentration. Diffusion tubes and color badges work similarly but are designed to determine the dose—concentration over time.

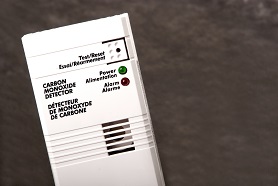

Portable CO detectors are often utilized to track ongoing CO exposure and monitor CO levels in confined-space entries. These devices typically feature a digital readout as well as visual and auditory alarms. When CO levels reach a preset value, the alarms will activate.

Fixed-location detectors are commonly used in industrial applications to monitor the concentration output at a fixed source. They’re equipped with visual and audible alarms. You can set these devices to display the concentration at the control box or use them with transmitters to detect CO in remote areas.